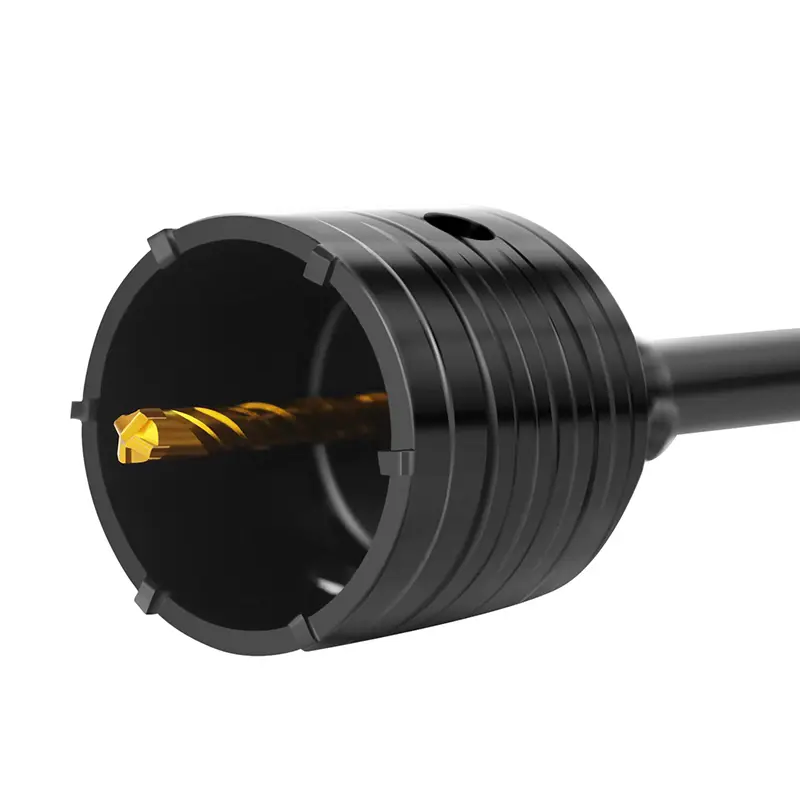

Tungsten Carbide Tipped Hole Saw Supplier in China - Quality Factory Direct

Looking for a high-quality Hole Saw for your cutting needs? Look no further than Wenzhou Ruiqi Tools Co., Ltd. and our Tungsten Carbide Tipped Hole Saw, Our hole saws are specifically designed for efficient and precise cutting of various materials including wood, plastic, and metal. The tungsten carbide tipped teeth provide superior cutting performance and durability, ensuring a longer lifespan for the saw. The sharp teeth also reduce the amount of effort required to cut through tough materials, making your job easier and more efficient, In addition, with a range of sizes available, our tungsten carbide tipped hole saws offer versatility for a wide range of cutting applications. Whether you are a professional tradesperson or a DIY enthusiast, our hole saws are the perfect choice for your cutting needs, Get your hands on a Wenzhou Ruiqi Tools Co., Ltd. Tungsten Carbide Tipped Hole Saw today and experience the difference in quality and performance

Avoiding Pitfalls Tungsten Carbide Tipped Hole Saw Industry Leaders Manufacturer

In the competitive landscape of the tungsten carbide tipped hole saw industry, it is crucial for both manufacturers and global buyers to navigate potential pitfalls effectively. Wenzhou Ruiqi Tools Co., Ltd., located in the Equipment Manufacturing Park of Wenzhou City, Zhejiang Province, stands out as a professional company dedicated to the development, production, and sale of high-quality accessories for pneumatic, construction, and electric tools. By prioritizing quality and innovation, Ruiqi has positioned itself as a leader in providing reliable solutions that meet diverse market needs. One significant challenge in the hole saw industry is the inconsistency in product quality. Many manufacturers may compromise on materials or production standards to reduce costs, resulting in tools that don't perform as expected. At Wenzhou Ruiqi Tools, we understand that consistent quality is key to building trust with global procurement professionals. Our tungsten carbide tipped hole saws are crafted from premium materials, ensuring durability and superior cutting performance across various applications. By investing in rigorous quality control and continuous improvement processes, Ruiqi ensures that we deliver products that not only meet but exceed the expectations of our clients. Another pitfall to avoid is the lack of comprehensive support and after-sales service. Global buyers often seek partners who can provide not only exceptional products but also robust support throughout the purchasing process. Wenzhou Ruiqi Tools prides itself on our customer-centric approach, offering tailored solutions and dedicated after-sales service to ensure a smooth experience from inquiry to delivery. By collaborating with us, procurement professionals can mitigate risks and enhance their supply chain efficiency, ensuring they receive the best value and performance from their investments in hole saw technology.

Avoiding Pitfalls Tungsten Carbide Tipped Hole Saw Industry Leaders Manufacturer

| Category | Specification | Application | Material Type | Durability (Cycles) |

|---|---|---|---|---|

| Standard Size | 1-1/4" | Wood, Plastic | Tungsten Carbide | 1000 |

| Large Diameter | 2-1/2" | Metal, Composite | Tungsten Carbide | 800 |

| Bi-Metal Hole Saw | 1-1/8" | Wood, Drywall | Bi-Metal | 900 |

| Heavy Duty | 3" | Brick, Masonry | Tungsten Carbide | 600 |

| Multi-Purpose | 1-3/8" | Wood, Metal | Tungsten Carbide | 850 |

Where the Value Lies Tungsten Carbide Tipped Hole Saw Custom Solutions, More Than a Supplier - A Partner

D

David Brown

Fantastic quality! The follow-up from the service team was a nice touch, showing their commitment to customer satisfaction.

05 July 2025

M

Mia Allen

Fantastic quality and very responsive service. I appreciate their dedication to customer care.

08 May 2025

G

Grace Phillips

I loved the quality of the product. Customer service representatives were prompt, friendly, and professional.

14 June 2025

M

Mila Martinez

The product is high-quality and the support team was very skilled in addressing my needs.

02 June 2025

E

Evan Hill

First-class product quality! Their customer service team is very professional and attentively supported me.

15 June 2025

M

Mia Smith

Impressive craftsmanship and remarkable customer service. The staff really knows how to take care of customers.

28 June 2025