Stainless Hole Saw Supplier in China - Quality Factory Direct Products

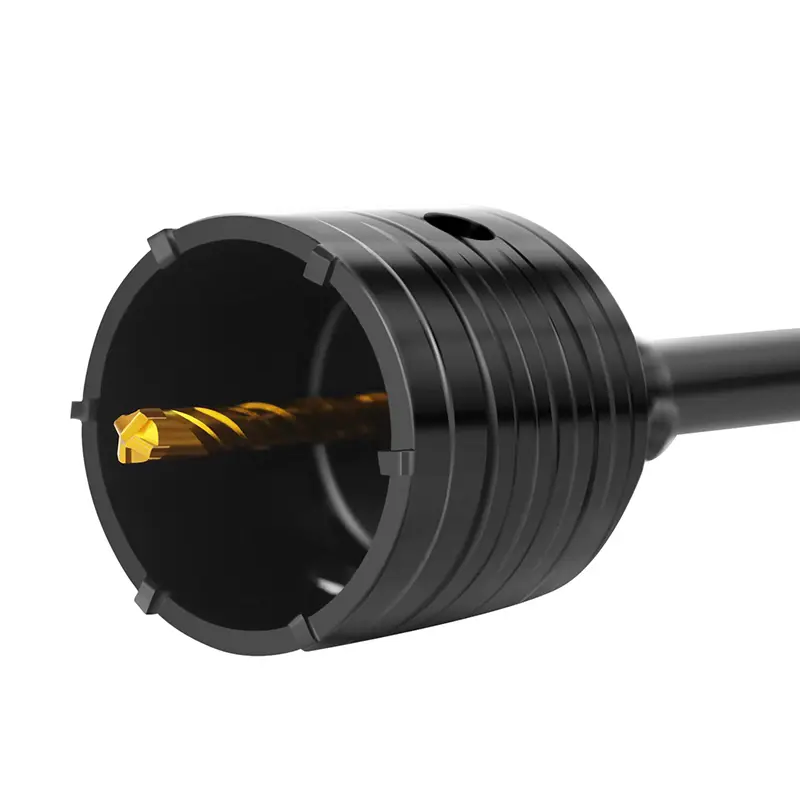

Discover the innovative StainleSs Hole Saw from Wenzhou Ruiqi Tools Co., Ltd. This high-quality cutting tool is specifically designed for drilling clean and precise holes in stainless steel materials. The hole saw features a durable stainless steel construction, ensuring long-lasting performance and resistance to corrosion. With sharp and efficient cutting teeth, it effortlessly cuts through stainless steel without causing any burrs or rough edges. The hole saw is available in various sizes to accommodate different hole diameters, providing versatility for various applications. Whether you are working on a DIY project or a professional construction job, the Stainless Hole Saw from Wenzhou Ruiqi Tools Co., Ltd. is the perfect tool for achieving accurate and smooth holes in stainless steel. Upgrade your drilling experience with this reliable and efficient hole saw, and see the difference for yourself

Best Methods To Stainless Hole Saw Guarantees Peak Performance Ahead of the Curve

When it comes to optimizing the performance of stainless hole saws, choosing the right methods is crucial for both manufacturers and global buyers. Wenzhou Ruiqi Tools Co., Ltd., a leading company in the development and production of accessories for pneumatic, construction, and electric tools, understands the significance of peak performance in today’s competitive market. Utilizing cutting-edge technology and high-quality materials, our stainless hole saws are designed to provide durability and efficiency, making them an ideal choice for industry professionals. To ensure the best performance of stainless hole saws, it’s essential to implement thorough maintenance and best practices. Regularly inspect the saws for wear and tear, and ensure they are properly lubricated before use. Selecting the right speed and feed rate according to the material being cut will also enhance the cutting efficiency and prolong the life of the tools. With our innovative designs and rigorous quality control, Wenzhou Ruiqi Tools stands at the forefront of the industry, guaranteeing that our stainless hole saws are not only effective but also exceed global standards. As global sourcing becomes increasingly important, partnering with a reliable manufacturer like Wenzhou Ruiqi Tools will assure you of superior performance and product reliability. Our commitment to quality and customer satisfaction enables businesses around the world to stay ahead of the curve in tool performance, allowing for seamless operations and exceptional results in various applications. Reach out to us today to learn how our advanced stainless hole saws can make a difference in your projects.

Best Methods To Stainless Hole Saw Guarantees Peak Performance Ahead of the Curve

| Method | Description | Material | Performance Rating (out of 10) | Recommended Usage |

|---|---|---|---|---|

| High-Speed Steel (HSS) | Versatile and durable, suitable for most metals. | HSS | 8 | General usage in metalworking. |

| Carbide-Tipped | Offers extended life and cutting ability for tough materials. | Tungsten Carbide | 9 | Use for hard metals and stainless steel. |

| Diamond-Coated | Ideal for ceramics and fiberglass. | Diamond | 10 | Best for non-metallic materials. |

| Nitride Coated | Enhances hardness and wear resistance. | HSS with Nitride | 7 | Suitable for medium-hard materials. |

| Cobalt | Great heat resistance for tough jobs. | Cobalt Steel | 8 | Heavy-duty applications. |

Best Strategies For Stainless Hole Saw Now Trending Industry Giant

L

Lucas Clark

Top-quality product! The after-sales service was outstanding, and the staff really knew their stuff.

01 June 2025

J

James Turner

The craftsmanship is outstanding! I appreciated how professional the service team was during my inquiries.

18 June 2025

M

Mason Howard

The quality of this product is impeccable. Customer service was responsive and incredibly helpful.

01 June 2025

A

Alyssa Scott

Superior quality! The after-sales service was prompt and courteous, making my experience delightful.

28 June 2025

S

Sophia Davis

The product is extraordinarily well-made! The knowledge and professionalism of the service team were impressive.

07 May 2025

I

Isaiah Baker

Impressive craftsmanship! The customer support provided was timely and highly professional.

12 May 2025