Metric Hole Saw from China Factory - Top Suppliers for Quality Tools

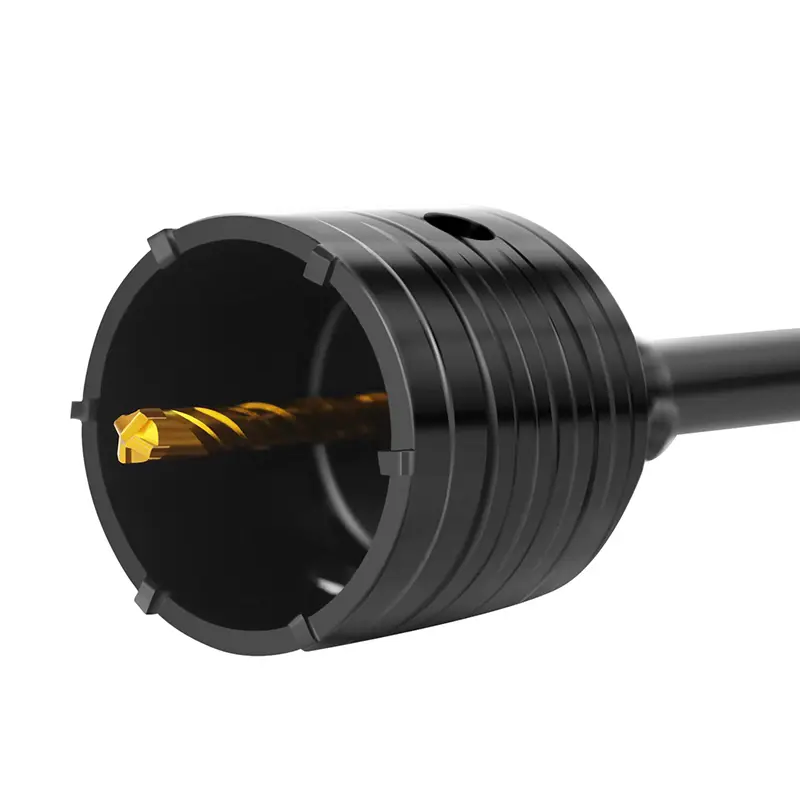

Discover the high-quality Metric Hole Saw from Wenzhou Ruiqi Tools Co., Ltd. This innovative tool is designed to provide precision and efficiency for your drilling needs, Our Metric Hole Saw is made of durable materials, ensuring a long lifespan and reliable performance. It features a sharp and sturdy cutting blade, capable of producing clean and accurate holes in various materials such as wood, plastic, metal, and drywall. The metric measurements make it easy to achieve precise hole sizes, eliminating the need for additional adjustments or modifications, With its ergonomic design, this hole saw offers comfortable handling and reduced fatigue during extended use. The versatile tool is suitable for both professional and DIY applications, making it an essential addition to any toolkit, Whether you are working on a construction project, home improvement tasks, or industrial applications, our Metric Hole Saw will exceed your expectations in terms of quality, functionality, and value. Experience the convenience and performance of this exceptional tool from Wenzhou Ruiqi Tools Co., Ltd

Key Steps to Choosing Metric Hole Saw From Concept to Delivery Products

Choosing the right metric hole saw is crucial for anyone involved in construction or manufacturing, as it directly impacts efficiency and product quality. At Wenzhou Ruiqi Tools Co., Ltd., we understand the intricacies of selecting the right tool to meet various project demands. Our expertise in developing and producing high-quality accessories for pneumatic, construction, and electric tools positions us well to guide global buyers through this process. The journey from concept to delivery starts with identifying your specific needs. Consider factors such as the materials you'll be cutting, the desired hole size, and the power source of your tools. Quality is paramount; therefore, selecting a manufacturer that adheres to rigorous quality standards will ensure durability and performance. Wenzhou Ruiqi Tools combines advanced manufacturing techniques with high-grade materials, thereby offering hole saws that withstand rigorous use and provide clean cuts every time. Once you have defined your requirements, the next step is to find a reliable supplier. Look for a company with a solid reputation and experience in the industry. At Ruiqi Tools, we pride ourselves on our commitment to excellence and customer satisfaction. Our products are designed to meet international standards, making us a preferred choice for global buyers. By choosing the right metric hole saw and partnering with a trusted manufacturer, you can significantly enhance the efficiency and outcomes of your projects.

Key Steps to Choosing Metric Hole Saw From Concept to Delivery Products

| Step | Description | Criteria | Tools Needed | Estimated Time (Days) |

|---|---|---|---|---|

| 1 | Define Requirements | Material type, thickness, and project scope | Requirement checklist | 2 |

| 2 | Research Options | Compare hole saw materials (bi-metal, carbide) | Market analysis tools | 3 |

| 3 | Select Supplier | Evaluate suppliers based on quality and pricing | Supplier evaluation matrix | 5 |

| 4 | Order Samples | Test performance on chosen materials | Order form and test setup | 7 |

| 5 | Finalize Purchase | Place bulk order while confirming specifications | Purchase order document | 2 |

| 6 | Delivery and Quality Check | Inspect delivered products for defects | Inspection checklist | 4 |

Champions of Metric Hole Saw Ahead of the Curve Trusted by Pros

M

Mia Allen

Fantastic quality and very responsive service. I appreciate their dedication to customer care.

08 May 2025

E

Ella Carter

The product is excellent and the customer service is equally impressive. They clearly prioritize customer satisfaction.

13 June 2025

H

Hannah Rogers

I really appreciated the quality of the product. The service team was prompt, professional, and very helpful.

27 May 2025

N

Natalie Allen

Impressive quality and wonderful customer service. The staff really knows their products!

04 June 2025

O

Oliver King

Quality craftsmanship is evident here. I was very impressed with the professionalism of their service team.

01 June 2025

M

Madison Allen

The quality of the product is remarkable, and the support staff were extremely professional and helpful.

09 May 2025