As we approach the 138th Canton Fair in 2025, the spotlight will be on innovations and trends within the tool industry, particularly focusing on the Large Hole Saw segment. Recent market analysis indicates that the global market for hole saws, including large variants, is projected to grow at a CAGR of approximately 5.5% over the next five years, driven by increasing construction activities and rising demand for efficient cutting tools in various industries. Furthermore, the shift towards automated and precision tools emphasizes the need for advanced Large Hole Saw technologies that meet evolving user requirements. The Canton Fair serves as a pivotal platform for industry leaders to showcase their latest advancements and gather valuable insights, ensuring that participants are well-informed about emerging trends and consumer demands in this niche market.

As we look towards 2025, the landscape of large hole saw technology is set to undergo significant transformations driven by innovation and evolving industry demands. According to a recent report by Global Industry Analysts, the global market for large hole saws is projected to reach approximately $850 million by 2025, reflecting a compound annual growth rate (CAGR) of 6.5% during the forecast period. This growth is propelled by the increasing demand for precision tools in construction, manufacturing, and DIY sectors.

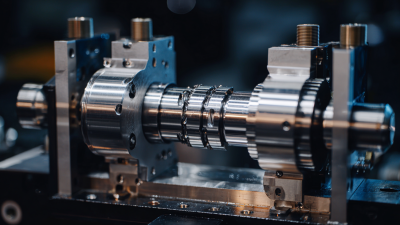

Emerging trends in large hole saw technology are primarily focused on enhancing durability and efficiency. Manufacturers are increasingly utilizing advanced materials, such as carbide-tipped and diamond-coated edges, which not only improve the lifespan of the tools but also enhance cutting performance on a variety of substrates. Additionally, the integration of smart technology into these tools is revolutionizing the user experience. Real-time data collection on usage patterns and wear levels is facilitating predictive maintenance, thereby minimizing downtime and operational costs. As we approach the 138th Canton Fair, industry professionals will be keenly watching these innovations that promise to redefine the future of large hole saws.

The growing demand for large hole saws in the construction and manufacturing sectors is closely tied to the anticipated expansion of the global power tools market. With projections estimating the market's size will rise from $29.69 billion in 2025 to $40.95 billion by 2032, a compound annual growth rate of 4.7% indicates a significant upward trend. This growth suggests an increasing reliance on efficient and precise cutting tools, particularly large hole saws, which are essential for a variety of applications, including HVAC installations and plumbing.

As industries evolve, technological advancements and innovative designs in large hole saws are also expected to play a crucial role. These tools must meet the growing demands for faster production times, durability, and versatility in varying materials. The upcoming 138th Canton Fair in 2025 will serve as a significant platform for manufacturers and suppliers to showcase their latest advancements, facilitating connections that may further drive the market forward. With a competitive landscape emerging, companies that prioritize research and development will likely gain a substantial advantage in capturing market share within this expanding sector.

The impact of automation and artificial intelligence (AI) on large hole saw production processes is rapidly transforming the industry. According to a recent report by MarketsandMarkets, the global automation market in manufacturing is projected to reach $214 billion by 2025, highlighting a significant trend towards integrating advanced technologies. This transition is driving efficiency, reducing labor costs, and enhancing precision in the production of large hole saws, which are increasingly in demand across various sectors, including construction and woodwork.

AI technologies play a crucial role in optimizing manufacturing processes. For instance, predictive maintenance powered by AI algorithms can foresee equipment failures before they occur, minimizing downtime and maintenance costs. A study by McKinsey indicates that AI applications can boost productivity in manufacturing by up to 20%, a figure that underscores the potential benefits for large hole saw manufacturers. Furthermore, implementing AI-driven quality control systems can ensure that each product meets stringent industry standards, thereby reducing waste and improving customer satisfaction. As the 138th Canton Fair approaches, stakeholders are keenly observing these trends, poised to adapt their strategies in response to the evolving landscape of large hole saw production.

| Aspect | Current Status | Future Trends | Impact of Automation and AI |

|---|---|---|---|

| Market Demand | Increasing demand in construction and industrial sectors | Growth in custom sizes and specialized applications | Improved forecasting and supply chain management |

| Production Technology | Traditional manufacturing processes | Adoption of advanced materials and manufacturing techniques | Increased automation for precision and efficiency |

| Sustainability | Moderate focus on environment-friendly practices | Shift towards sustainable materials and processes | AI-driven assessments of resource usage |

| End-User Applications | Widely used in HVAC, plumbing, and electrical sectors | Expansion into renewable energy sectors | Smart analytics for improving user experience |

| Competitiveness | High competition among manufacturers | Emergence of new players focusing on innovation | AI tools for market analysis and strategy development |

The 138th Canton Fair in 2025 is poised to showcase the latest advancements in large hole saw technology, particularly with a focus on sustainability. As the tool manufacturing industry increasingly prioritizes eco-friendliness, many companies are investing in research and development to create innovative, environmentally responsible products. According to a recent industry report by ResearchAndMarkets, the global market for eco-friendly tools is expected to grow at a CAGR of 6.5% from 2023 to 2028, driven by heightened consumer awareness and regulatory pressures for sustainable manufacturing practices.

In this context, large hole saws are evolving with materials and designs that minimize waste and environmental impact. Manufacturers are now utilizing recycled metals and biodegradable coatings, which contribute to a reduced carbon footprint during production. Additionally, advancements in production techniques, such as additive manufacturing, allow for more efficient use of raw materials. A report by Grand View Research suggests that approximately 70% of tool manufacturers are exploring sustainable designs as a key strategy for their long-term growth. At the Canton Fair, industry leaders will likely share insights into these innovations, highlighting how embracing sustainability not only benefits the environment but also enhances product performance and marketability.

As the 138th Canton Fair approaches in 2025, the dynamics of global trade surrounding large hole saws are expected to undergo significant shifts. Increasing demand for specialized cutting tools across various industries, including construction and manufacturing, indicates a robust market for both exports and imports. Key players are likely to refine their supply chains in response to evolving consumer preferences and technological advancements, which will impact pricing strategies and product offerings.

Moreover, emerging markets in Asia and Africa are projected to witness a surge in large hole saw usage, driven by rapid urbanization and infrastructure development. This trend presents opportunities for exporters to tap into these growing markets by providing innovative products tailored to regional needs. Simultaneously, established manufacturing hubs in North America and Europe may face challenges from competitive pricing and enhanced manufacturing techniques developed in other regions, compelling them to adapt to retain their market share.