Choosing the right Steel Hole Saw is crucial for maximizing performance and ensuring durability in various cutting applications. According to a recent industry report by Research and Markets, the global hole saws market is expected to grow significantly, driven by advancements in manufacturing processes and increasing demand from the construction and automotive sectors. Selecting the appropriate Steel Hole Saw can reduce downtime and enhance cutting efficiency, as well as prolong the life of the tool. For instance, the right choice can lead to a decrease in wear and tear by up to 30%, as noted by cutting tool experts at Tooling & Manufacturing Association. Understanding the specific materials and applications in which a Steel Hole Saw will be used is essential for achieving optimal results, making informed selection vital for professionals in the field.

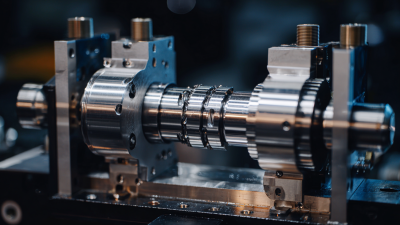

When selecting the right steel hole saw, it's crucial to understand the different types available, as each serves specific purposes and material compatibilities. Bi-metal hole saws, for example, are versatile and well-suited for cutting through a variety of materials, including metal and wood. Their design combines high-speed steel teeth with a tough backing material, offering both toughness and sharpness for efficient cutting while providing durability.

On the other hand, carbide-tipped hole saws excel in cutting through hard or abrasive materials, such as stainless steel or masonry. They feature a tougher blade that withstands heat and resist wear, making them ideal for heavy-duty applications. It's also essential to consider the size and tooth configuration of the hole saw, as different projects may require specific diameters or tooth counts to achieve the desired finish. Understanding these distinctions will help ensure optimal performance and longevity, allowing you to tackle a wide range of tasks effectively.

When selecting a steel hole saw, several key features should be prioritized to ensure optimal performance and durability. Firstly, the material and construction of the hole saw are crucial. High-speed steel (HSS) is commonly preferred for its ability to withstand high temperatures and resist wear, making it suitable for cutting through various metals. Additionally, look for hole saws with a hardened tooth design, which enhances cutting efficiency and extends the tool's lifespan.

When selecting a steel hole saw, several key features should be prioritized to ensure optimal performance and durability. Firstly, the material and construction of the hole saw are crucial. High-speed steel (HSS) is commonly preferred for its ability to withstand high temperatures and resist wear, making it suitable for cutting through various metals. Additionally, look for hole saws with a hardened tooth design, which enhances cutting efficiency and extends the tool's lifespan.

Another important aspect is the size and depth of the hole saw. It's essential to choose a saw that matches the diameter required for your project while also considering the depth of the cut. A deeper hole saw can be beneficial for thicker materials, allowing for more versatility in applications. Furthermore, the pitch of the teeth can impact performance; finer teeth are ideal for metal applications, while wider teeth help in cutting through softer materials. By carefully evaluating these features, you can make an informed choice to achieve the best results in your drilling tasks.

When selecting a steel hole saw for your projects, evaluating the size and compatibility is crucial for achieving optimal performance. The size of the hole saw directly impacts the diameter of the holes you can create, which means that understanding the specific requirements of your project is essential. Whether you are working on plumbing, electrical installations, or woodworking, choosing the correct size ensures that your holes will meet the specifications needed for fittings, connectors, or aesthetic purposes.

Compatibility with your tools and materials is another factor that can influence your choice. Not all hole saws work with every drill type, so it's important to check the mounting system used by your drill to ensure a secure fit. Additionally, consider the material you are cutting; some hole saws are designed for specific applications, such as metal, wood, or composite materials. By assessing both size and compatibility, you can select a steel hole saw that not only enhances your project's efficiency but also maintains durability over repeated use.

When it comes to enhancing the performance and longevity of steel hole saws, proper maintenance is key. Regular cleaning after each use can significantly improve the lifespan of your tools. Residue build-up can affect the cutting efficiency, so using a wire brush to remove any debris is recommended. Moreover, lubricating the hole saw with cutting oil not only helps in facilitating smoother cuts but also reduces wear and tear on the teeth.

Another important aspect to consider is the storage of your hole saws. Placing them in a protective case will prevent damage and corrosion. According to industry reports, maintaining optimal storage conditions can increase the longevity of these tools by up to 30%. It’s also wise to regularly inspect your hole saws for any signs of wear or damage—this proactive approach ensures you replace them before they compromise your projects.

In addition, choosing the right drill bit can make a substantial difference in performance. Data from recent testing indicates that a well-constructed drill bit can enhance precision and reduce the likelihood of breakage. For best results, match the drill bit with the specific material you’re working with, ensuring a clean and efficient drilling process.

| Dimension | Recommendation | Maintenance Tips | Expected Lifespan (Holes) |

|---|---|---|---|

| Diameter | Choose based on material thickness | Clean after each use | 50-100 |

| Thickness | Opt for thicker for tougher materials | Lubricate before use | 100-200 |

| Teeth Design | Bi-metal for versatility | Inspect teeth regularly | 70-150 |

| Coating | Choose carbide-coated for longevity | Store dry and cool | 200+ |

When selecting a steel hole saw, it’s crucial to avoid common mistakes that can lead to subpar performance and quick wear. One frequent error is neglecting to consider the material thickness you'll be cutting. Using a hole saw that's not designed for the specific gauge of the material can result in uneven cuts or even tool breakage. Ensure the saw's specifications match your project needs, from the thickness of the steel to the desired hole diameter.

Another mistake is overlooking the importance of tooth design and pitch. Different applications require different types of teeth; for example, finer teeth may be better for thicker materials while larger, more aggressive teeth are suited for softer metals. Additionally, not paying attention to the hole saw's coating can also be detrimental. A poorly coated saw may struggle with durability and become worn out rapidly. To maximize longevity and efficiency, choose a hole saw with a high-quality finish suited for your cutting needs.