Choosing the right door hole saw for your next project can significantly impact the efficiency and quality of your work. With a plethora of options available on the market, it’s crucial to understand the specific needs of your project before making a purchase. Whether you're installing new hardware, creating pass-throughs for doorknobs, or fitting locks, selecting the appropriate door hole saw can save you time and ensure precision. Factors such as the material of the door, the size of the hole required, and the type of saw teeth can all influence your decision. In this guide, we will explore essential considerations and tips to help you navigate through the various types of door hole saws, ensuring you make an informed choice that aligns perfectly with your project requirements.

When selecting a door hole saw for your project, it’s essential to understand the various types available in the market. Door hole saws come in several designs, primarily differentiated by their material and the specific size of the hole they create. For instance, bi-metal hole saws are popular due to their durability and versatility, making them suitable for both wood and metal surfaces. Conversely, carbide-tipped saws are ideal for harder materials and provide a longer lifespan, albeit at a higher cost.

Another factor to consider is the size range of the hole saws. They typically come in standard sizes, such as 2-1/8 inches for door knobs or 1-inch for deadbolts. It's crucial to choose a size that matches your door hardware specifications to ensure a perfect fit. Additionally, some manufacturers offer adjustable hole saws that can accommodate multiple sizes, adding convenience for various projects. By understanding these differences, you can make an informed decision and select the best door hole saw to meet your specific needs.

When selecting the right door hole saw, understanding the appropriate size for your specific project is crucial. According to a report by the Home Improvement Research Institute, choosing the correct diameter is essential, as it directly impacts the fitting of the door hardware. Standard door knob holes typically require a 2-1/8 inch hole saw, while deadbolt locks typically use a 1 inch hole. A survey conducted by the National Association of Home Builders indicates that incorrectly sized holes are one of the top three causes of door installation delays, highlighting the importance of proper sizing.

Additionally, the material composition of the door can influence the size and type of hole saw used. For instance, wood doors may require a different approach compared to fiberglass or metal doors. A study published in the Journal of Wood Science found that using a hole saw that is too small can result in splintering and damage to the door, potentially leading to costly repairs. Consequently, ensuring you have the right size hole saw not only facilitates a smoother installation process but can also enhance the longevity and aesthetic appeal of your door hardware.

When selecting a door hole saw for your next project, there are several key features to consider to ensure you make the right choice. First and foremost, the size of the hole saw is critical. Different door hardware, such as knobs and deadbolts, require specific hole sizes. According to a report by the American National Standards Institute (ANSI), the most common sizes for residential doors are typically 2-1/8 inches for cylindrical locks and 1-inch for deadbolts. Ensuring that you have the appropriate size for your intended hardware will facilitate a smoother installation process.

Another important factor to consider is the material and type of cutting teeth used in the hole saw. High-speed steel (HSS) or bi-metal hole saws are popular choices due to their durability and ability to cut through a variety of materials, including wood, fiberglass, and soft metal. A study published in the Journal of Industrial Materials indicates that bi-metal hole saws can last up to three times longer than regular steel saws, reducing the frequency of replacements and improving overall efficiency in projects. Additionally, look for hole saws with optimal tooth configurations for faster and cleaner cuts, which can significantly enhance the quality of your work.

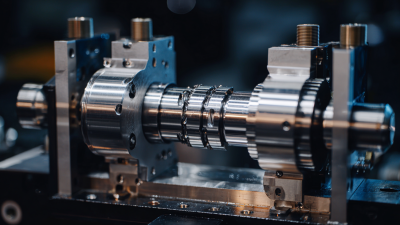

When selecting a hole saw for your next project, understanding the quality of materials is critical. Hole saws are primarily made from steel and carbide, each offering different benefits depending on the nature of the job. Steel hole saws are typically more affordable and work well for softer materials like wood and drywall. They are versatile and suitable for general use, but their durability and cutting performance in tougher materials may fall short over time.

On the other hand, carbide hole saws deliver superior performance, especially in harder materials such as metal and composite products. According to industry reports, carbide hole saws demonstrate a significantly higher lifespan compared to their steel counterparts, often outlasting them by up to 50%. This durability translates to better efficiency on the job site, reducing the need for frequent replacements. As the market for bi-metal band saw blades is projected to grow with rising demand, professionals should consider investing in high-quality carbide hole saws for projects that require precision and longevity in tough conditions.

| Feature | Steel Hole Saws | Carbide Hole Saws |

|---|---|---|

| Durability | Moderate | High |

| Cutting Speed | Standard | Faster |

| Material Compatibility | Wood, Soft Metals | Hard Metals, Composites |

| Cost | Lower | Higher |

| Life Span | Limited | Extended |

| Heat Resistance | Low | High |

When it comes to choosing a door hole saw, understanding its maintenance and proper use is vital for ensuring an efficient and long-lasting performance. According to a report by the Tool and Fastener Institute, nearly 60% of contractors reported that improper maintenance of their tools led to decreased efficiency and increased costs in their projects. A well-maintained hole saw not only provides cleaner cuts but also minimizes wear and tear. Regularly inspect the teeth for dullness and replace them if necessary. Utilize a light lubricant while cutting to reduce friction and heat, which can significantly extend the life of the saw.

Proper use techniques also play a crucial role in maximizing the performance of your door hole saw. The American National Standards Institute (ANSI) recommends using a low-speed setting for softer materials and a higher speed for harder woods. Moreover, applying steady pressure without forcing the tool can lead to smoother and more accurate cuts, drastically reducing the likelihood of chipping. Lastly, always ensure that the saw is securely attached to the drill and use a pilot drill bit to help guide the hole saw, especially in wooden doors, to achieve precise results while minimizing any wobble.