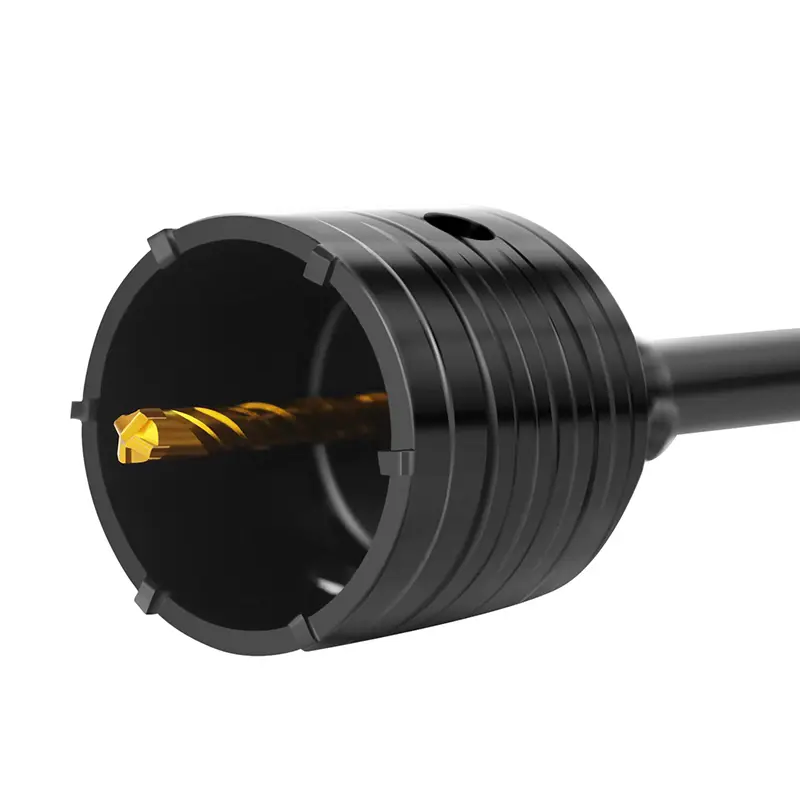

65mm Diamond Hole Saw - Top China Manufacturer & Reliable Suppliers

Discover the superior quality and precision of our 65mm Diamond Hole Saw, proudly manufactured by Wenzhou Ruiqi Tools Co., Ltd. This professional-grade tool is designed to effortlessly cut through various materials such as glass, ceramic, porcelain, granite, and marble, The diamond-tipped drill bit ensures a clean and accurate hole, while the durable construction allows for long-lasting performance. The 65mm size is perfect for creating large holes for plumbing, electrical work, and other installation projects. The hole saw features high resistance to wear and tear, providing reliable and consistent results with each use, Whether you are a professional tradesperson or a DIY enthusiast, our Diamond Hole Saw is an essential addition to your tool collection. Trust in the expertise of Wenzhou Ruiqi Tools Co., Ltd. to deliver top-quality products that meet the demands of your projects. Invest in the 65mm Diamond Hole Saw and experience the efficiency and precision it offers for all your hole-cutting needs

10 Essential Tips For 65mm Diamond Hole Saw Guarantees Peak Performance Service

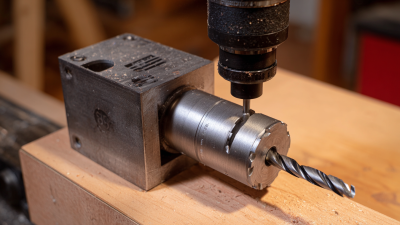

When it comes to optimizing performance and longevity in drilling, using a high-quality 65mm diamond hole saw is essential. At Wenzhou Ruiqi Tools Co., Ltd., we specialize in manufacturing premium accessories for pneumatic, construction, and electric tools, and we understand the critical factors that ensure peak performance for users worldwide. Here are ten essential tips to maximize the efficiency and service life of your diamond hole saw. First and foremost, always select a diamond hole saw that fits your specific application. Consider the material you'll be drilling—be it ceramic, glass, or concrete—as each material may require a different type of diamond grit or design. Furthermore, maintaining an optimal cutting speed and applying consistent pressure will prevent overheating and extend the life of the drill. Use a cooling lubricant, such as water or specialized cutting fluid, to enhance the 65mm diamond hole saw's performance while minimizing wear on the tool. Lastly, regular inspection and cleaning of your diamond hole saw will help identify any wear or damage early on, preventing costly breakdowns during critical projects. Proper storage is equally important; store your hole saws in a dry, cushioned environment to avoid impact damage. By following these tips, you can guarantee not only peak performance service but also maximize your investment in high-quality drilling solutions, ensuring you achieve exceptional results with every project. Trust Wenzhou Ruiqi Tools Co., Ltd. for the best in tool accessories that deliver reliability and innovation.

10 Essential Tips For 65mm Diamond Hole Saw Guarantees Peak Performance Service

| Tip No. | Tip Description | Benefits |

|---|---|---|

| 1 | Use a Slow Speed | Increased control and longer tool life. |

| 2 | Lubricate Regularly | Reduces friction and heat buildup. |

| 3 | Mark Cutting Points | Enhances accuracy and prevents slipping. |

| 4 | Keep the Saw Cool | Prevent premature wear and breakage. |

| 5 | Use Appropriate Pressure | Balanced cutting speed and efficiency. |

| 6 | Select the Right Material | Optimizes cutting performance and longevity. |

| 7 | Maintain a Steady Hand | Ensures clean and precise cuts. |

| 8 | Regularly Inspect for Wear | Identifies maintenance needs before failure. |

| 9 | Store Properly | Protects against damage and prolongs life. |

| 10 | Follow Manufacturer Guidelines | Ensures optimal compatibility and use. |

How To Decide Between 65mm Diamond Hole Saw Where Service Meets Innovation Service Backed by Expertise

L

Laura Wilson

This product is a game-changer! The service team was professional and genuinely cared about my needs.

26 May 2025

G

Grace Phillips

I loved the quality of the product. Customer service representatives were prompt, friendly, and professional.

14 June 2025

I

Isaiah Diaz

Excellent quality! The after-sales service team was knowledgeable and genuinely helpful.

16 June 2025

M

Mia Smith

Impressive craftsmanship and remarkable customer service. The staff really knows how to take care of customers.

28 June 2025

J

Jackson Lee

The product is very well-made, and the after-sales team was responsive and incredibly helpful.

18 June 2025

A

Asher Young

Top-notch quality! The service after my purchase was prompt and showcased their dedication to customers.

21 June 2025