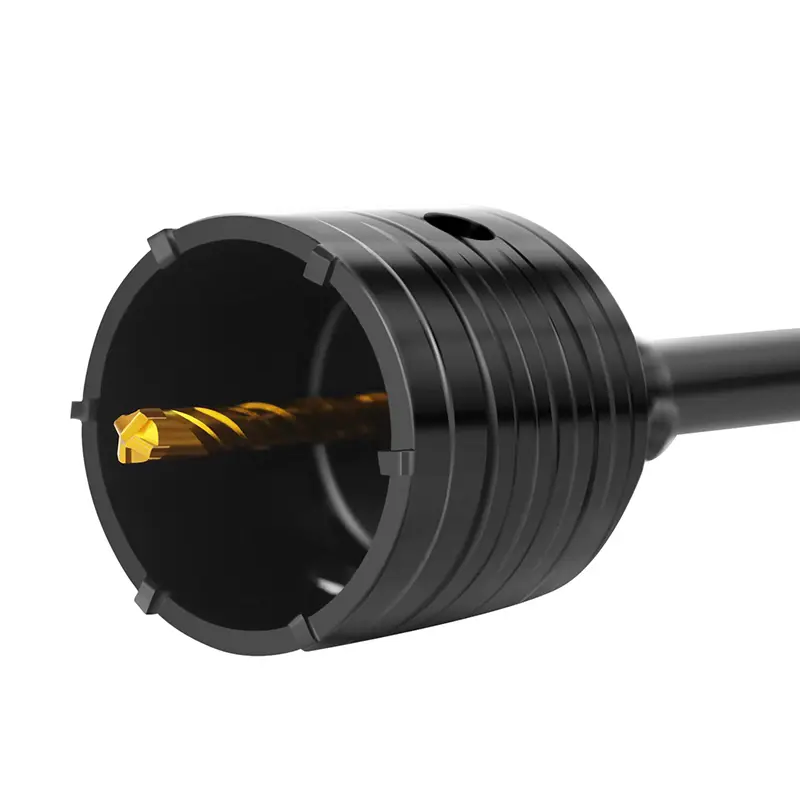

32mm Tile Hole Saw - Top China Suppliers & Manufacturers for Quality

Looking for a reliable and efficient tool to cut perfectly round holes in tiles? Look no further than the 32mm Tile Hole Saw from Wenzhou Ruiqi Tools Co., Ltd, Our hole saw is designed with sharp and durable carbide teeth that can easily cut through ceramic, porcelain, and other types of tiles. The 32mm size is perfect for creating holes for pipes, faucets, and other fixtures with precision and ease, Equipped with a centering drill bit, this hole saw ensures accurate placement and smooth cutting without wandering. The arbor and pilot drill are also included for your convenience, making it a complete and practical tool for your tile cutting needs, With a sturdy construction and high-quality materials, our 32mm Tile Hole Saw is built to last and can withstand tough and continuous use. Whether you are a professional tradesperson or a DIY enthusiast, this tool is a must-have for any tile installation or renovation project, Trust Wenzhou Ruiqi Tools Co., Ltd. to provide you with the reliable and effective tools you need for your projects. Order our 32mm Tile Hole Saw today and experience the difference in quality and performance

Best Practices For 32mm Tile Hole Saw Service Dominates

When it comes to enhancing efficiency and precision in tile installation projects, the importance of choosing the right tools cannot be overstated. At Wenzhou Ruiqi Tools Co., Ltd., we specialize in the production of high-quality accessories for pneumatic, construction, and electric tools, including our standout product, the 32mm tile hole saw. In this blog, we will explore best practices for utilizing 32mm tile hole saws that can help you maximize their potential while ensuring a smooth operation. To achieve optimal results, first ensure that you're using the right drill speed and pressure when operating a 32mm tile hole saw. A slower speed is generally more effective for tile materials, allowing the saw to cut through without cracking the surface. Additionally, securing your tile firmly during the drilling process can prevent movement and enhance accuracy. Ensuring that your tools are well-maintained, with sharp blades and clean edges, will also contribute to achieving clean holes with minimal effort. Finally, safety should always be a priority. Wearing proper protective gear, including goggles and gloves, will safeguard against potential injuries during the drilling process. At Wenzhou Ruiqi Tools Co., Ltd., we are committed to providing you with the finest tools that not only meet international standards but also adapt to the diverse needs of global buyers. By following these best practices, you can revolutionize your tile installation process and ensure exceptional results every time.

Best Practices For 32mm Tile Hole Saw Service Dominates

| Practice | Description | Benefits | Frequency |

|---|---|---|---|

| Regular Maintenance | Inspect and clean the hole saw after each use. | Increases longevity and performance. | After Each Use |

| Proper Lubrication | Use appropriate cutting oil to reduce friction. | Improves cutting speed and life span. | Before Each Use |

| Correct Speed Settings | Adjust drill speed according to material. | Reduces overheating and breakage. | With Each Material Change |

| Use of Guide Plates | Employ guide plates for accurate drilling. | Enhances precision and prevents wandering. | Always |

| Safety Gear | Wear goggles and gloves during operation. | Ensures personal safety and prevents injuries. | Always |

Top 3 32mm Tile Hole Saw Service Backed by Expertise Factory-Direct Excellence

M

Michael Thompson

The durability of the items I purchased is outstanding. The service representatives were knowledgeable and very helpful.

17 May 2025

A

Ava Hernandez

The team went above and beyond in providing outstanding customer service. The product itself is fantastic.

20 June 2025

Z

Zoey Diaz

The product quality is impressive and the support staff provided detailed assistance and follow-ups.

19 May 2025

N

Nathaniel Wood

Top-notch quality! The professionalism of the service team was impressive and made the process smooth.

20 June 2025

C

Chloe Hughes

Absolutely love this product! The after-sales team was prompt and highly professional.

17 May 2025

C

Cole Turner

High-quality product! The after-sales team was highly professional and very mindful of my needs.

23 June 2025